Cork vs. foam: Choosing long-term durability

(This article was written by Amorim Cork Composites)

The visual and design component is one of the most valued aspects when it comes to floor installations or renovation projects. However, it is important to consider the foundation on which the new floor will be laid: the subfloor. This material layer, placed between the concrete (or the previous floor in case of renovation) and the final floor, is essential to ensure the durability of the floor over time.

Durability: an important point when choosing an underlay

Contents

In an online survey conducted recently by Amorim Cork Composites on the US market, consumers cited durability as the number one reason for installing a subfloor.

To better understand customer needs, we gathered the opinion of more than 300 people who were planning to install a new floor in their home or who have recently installed a new floor. According to the results, consumers who chose to install subfloors stated that their most valued performance characteristic is the durability this solution brings to the floor.

Cork or 100% foam: which underlay is more durable?

Given the need for durability and the wide range of solutions available on the market, why choose a cork underlay over a 100% foam based solution? To answer this question, we ran two different tests.

Dynamic Load Test*

The dynamic load test is a laboratory test that simulates the pressure exerted on the floor by, among other things, pedestrians, trolleys and office chairs with castors. To be effective, the underlay must be able to withstand this pressure without losing its absorbent properties.

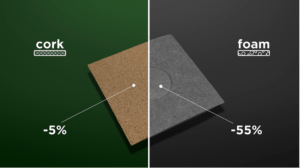

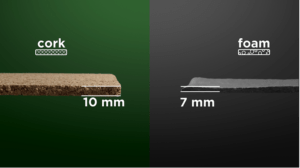

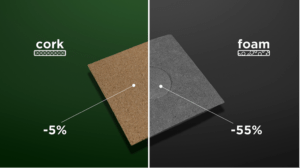

To assess material performance, we subjected a cork sample and another foam assembly – both 10 mm thick – to 100,000 cycles at a pressure of 75 KPa.

Cork subfloors have proven to perform significantly better compared to the 100% foam-based solution, while retaining their properties. After 100,000 charging cycles, cork lost only 5% of its thickness, while foam recorded a 55% loss.

Creep test*

The creep test determines the weight that can be placed on a given floor over time, with a reference period of 10 years. For example, we are talking about furniture weight. In a comparison test between a cork sample and another 100% foam based sample, the cork sample was found to have a higher resistance to compressive creep due to its resilience. This means that as cork compresses over the years, it retains its thickness and therefore the performance of the system it is applied to, whereas foam (PU, PE or PP) loses its underlayer when the pressure results in cell rupture. density and effectiveness.

In short, the tests carried out have shown that a cork-based underlay is the best option to ensure the durability and performance of the floor over a longer period of time. Therefore, choosing a cork solution translates into savings for the consumer, avoiding premature floor replacement. In addition, with a cork solution, users can enjoy the comfort that an underlay has to offer for years to come, just as on the first day it was installed.

(*tests carried out in independent and certified laboratories)

Performance and durability

In addition to performance, cork-based underlays are also a more sustainable choice than foam-based solutions from an environmental point of view.

In the case of Amorim’s subfloors, according to independent research conducted by EY consultant, all products analyzed have a negative carbon balance when looking at carbon sequestration of cork oak forests and production-related emissions. This means that the carbon capture of cork-based subfloors is greater than the CO2 capture resulting from their production.

Our brands: Acousticork and Go4Cork

Currently, Amorim Cork Composites offers a wide range of underlays that adapt to all floor types. Whether it is a laminate, wood or ceramic floor, there is an Amorim underlay that adapts to your flooring needs and provides a quieter and more comfortable environment.

Comments are closed.