Key Takeaways

Contents

- 1 Key Takeaways

- 2 Pump Maintenance Checklist | Importance of Pump Maintenance

- 3 Developing a Pump Maintenance Program

- 4 Daily Maintenance Checklist

- 5 Monthly Maintenance Checklist

- 6 Quarterly Pump Maintenance Steps

- 7 Annual Pump Maintenance Guidelines

- 8 Customizing Your Maintenance Checklist

- 9 Troubleshooting Common Pump Issues

- 10 Conclusion

- 11 FAQS

- 11.1 What should I include in my monthly pump maintenance routine to ensure the longevity and efficiency of my pumps?

- 11.2 How can I create an effective pump maintenance checklist to ensure I properly check the pump and inspect the shaft pump?

- 11.3 What specific tasks should I prioritize in my pump maintenance checklist to effectively check oil leaks and shaft runout?

- 11.4 How should I structure my pump maintenance checklist to effectively check oil leaks and check shaft conditions?

- 11.5 What actions should I take in my pump maintenance checklist to ensure I can effectively check oil leaks and monitor shaft performance?

- 11.6 How can I ensure that my pump maintenance procedures are comprehensive and cover all necessary aspects of pump upkeep?

- Significance of upkeep for pumps and its impact on performance

- Creating an effective program for pump maintenance

- Routine daily tasks to ensure pump functionality

- Essential checks to be performed monthly on pumps

- Key procedures for quarterly maintenance of pumps

- Comprehensive guidelines for annual pump servicing

- Tailoring your maintenance checklist to specific needs

- Identifying and resolving frequent pump problems

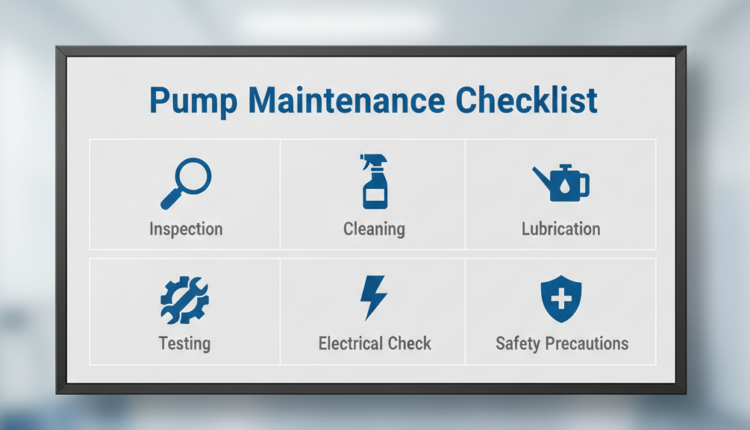

Pump Maintenance Checklist | Importance of Pump Maintenance

A well-structured pump maintenance checklist is crucial for ensuring the longevity and efficiency of pumps across various applications. Regular maintenance and repairs not only prevent unexpected failures but also reduce downtime and operational costs. Key components of a maintenance checklist should include inspecting check valves, monitoring for leaks, and performing routine maintenance tasks that enhance performance. Implementing a preventive maintenance strategy allows operators to anticipate potential issues before they escalate, ensuring that each pump functions optimally. Prioritizing a comprehensive pump maintenance checklist can significantly impact the overall reliability of the system and help avoid costly repair and maintenance procedures.

Benefits of Regular Pump Maintenance

Regular pump maintenance plays a crucial role in ensuring the longevity and efficiency of pumps, including water pumps and sump pumps. By adhering to a well-structured pump maintenance checklist, operators can minimize the need for costly corrective maintenance down the line. Preventative maintenance not only extends the life of the equipment but also decreases the likelihood of unexpected repairs. By ensuring that pumps are regularly serviced, the efficiency of drain cleaners and pipe cleaners can be maximized, resulting in better overall system performance.

Implementing a comprehensive pump maintenance checklist allows for the identification of potential issues before they escalate into major problems. Routine checks can help spot wear and tear, leading to timely repairs that save both time and resources. Regular maintenance fosters reliability in pump operation, which is essential for any water management system. Prioritizing a systematic approach to pump maintenance ensures that all components function properly, ultimately enhancing productivity and reducing the risk of emergency situations.

Impact of Neglecting Pump Maintenance

Neglecting proper pump maintenance can lead to significant operational disruptions. A thorough pump maintenance checklist is essential for ensuring the longevity and efficiency of various pump types, including centrifugal pumps and submersible pumps. Without regular inspections, issues such as leakage may go unnoticed. This can result in water damage, increased energy consumption, and decreased performance. Sump pumps and feed pumps require diligent oversight to prevent costly repairs down the line.

The ramifications of inadequate maintenance extend to plumbing systems as well. Regular checks help identify wear and tear on machinery, aiding in the early detection of potential failures. A clear maintenance checklist allows operators to efficiently monitor critical components. Overlooking even minor details can compromise the entire system’s functionality, making routine inspections indispensable for maintaining optimal pump operation.

Developing a Pump Maintenance Program

Creating a structured pump maintenance program involves incorporating a comprehensive pump maintenance checklist that addresses the specific requirements of different types of pumps. Regular inspections of centrifugal pumps and condensate pumps are essential to ensure efficient operation. Key components include assessing the condition of valves, including throttle valves, and performing maintenance on hydraulic systems. Daily checks may involve monitoring equipment such as pressure washers and drain tiles to prevent potential issues. Staying proactive with a detailed pump maintenance checklist ensures that all critical components, including washers and seals, receive appropriate attention to avoid unexpected failures.

Key Components of an Effective Program

An effective pump maintenance program begins with a comprehensive pump maintenance checklist tailored to the specific needs of the equipment. This checklist should include regular inspections of critical components such as washers and valves, ensuring proper functionality and preventing leaks. Technicians must also assess the condition of the boiler and evaluate any signs of corrosion that may compromise performance. Safety should not be overlooked; protective equipment is essential during maintenance tasks to minimize the risk of injury.

Backup power systems are another vital element of a successful maintenance program. These systems help ensure that pumps remain operational during power outages, preventing potential damage. Regularly scheduled maintenance, as outlined in the pump maintenance checklist, should also take into account warranty requirements to keep the equipment covered. Finally, proper drain management contributes to the overall efficiency of the pumping system, allowing for swift removal of contaminants and maintaining peak performance.

Setting Maintenance Schedules

Establishing a routine for maintenance schedules is crucial for efficient operation. Incorporating a pump maintenance checklist allows technicians to monitor vital components such as bearings and discharge pressures. Regular vibration analysis can help identify issues before they escalate, ensuring that potential leaks or mechanical failures are addressed promptly. A well-structured pump maintenance program can effectively minimize downtime and extend the lifespan of the equipment.

Creating maintenance timelines requires clear insights into operational demands and equipment usage. Understanding how to develop a pump maintenance checklist tailored to specific systems, including HVAC applications, enhances reliability. Regularly scheduled checks can prevent minor issues from turning into significant concerns, thereby safeguarding investments. Implementing a comprehensive pump checklist helps ensure all necessary procedures are performed consistently and effectively.

- Develop a detailed maintenance calendar outlining specific tasks.

- Train staff on the importance of adhering to the maintenance schedule.

- Use digital tools or software to track maintenance activities and reminders.

- Review and update the maintenance checklist regularly based on feedback and results.

- Schedule inspections during off-peak hours to minimize disruption.

- Document all maintenance performed to assess trends and inform future schedules.

- Encourage a culture of proactive maintenance among all team members.

Daily Maintenance Checklist

A well-structured pump maintenance checklist is essential for ensuring the efficiency and longevity of pump systems. Focusing on daily pump maintenance tasks helps identify issues early, preventing costly breakdowns. This daily maintenance checklist should include checking pump fluid levels, monitoring vibration and noise levels, and inspecting seals and connections. Implementing a preventive maintenance pump strategy allows for timely interventions and safeguards against unexpected failures. Regular updates to the maintenance checklist ensure it remains comprehensive, catering to specific machinery requirements and operational needs. A robust pump maintenance schedule that incorporates these elements guarantees optimal performance and reliability.

Overview of Daily Tasks

Daily tasks are essential for effective pump maintenance. A comprehensive pump maintenance checklist should include routine inspections of the pump to identify any immediate needs. Regularly inspecting the pump aids in detecting potential issues early, allowing for preventative pump maintenance to be carried out before major problems arise. Specific maintenance procedures might involve checking sump pump maintenance, which ensures that sump pump repairs are minimized and operational efficiency is maintained.

Clean pump components regularly to prevent debris buildup that could impede performance. The pump monitoring requirements should be adhered to by documenting any operational changes or unusual noises. Maintenance work should reflect the unique demands of each pump and align with a well-structured maintenance program. Establishing a daily routine for these tasks ensures the longevity and reliability of the pump, making it easier to follow the pump maintenance checklist effectively.

Common Issues to Check Daily

Regular inspection is a vital aspect of a pump maintenance checklist. A standard maintenance routine should include checking for unusual vibrations and listening for abnormal noises from the centrifugal pump. Inspecting the shaft pump for signs of wear or misalignment helps in identifying potential issues early on. Testing pumps daily for proper operation ensures that a well-maintained pump continues to function efficiently and prevents unexpected pump failure.

Assessing fluid levels and monitoring for leaks are essential maintenance procedures that should be performed daily. Ensuring that seals and gaskets are in good condition can significantly extend the life of the equipment. A well-executed maintenance program can decrease the likelihood of needing a replacement pump. Timely inspections and adherence to a comprehensive pump maintenance checklist are critical in maintaining optimal performance and reliability.

Monthly Maintenance Checklist

A well-structured pump maintenance checklist is essential for ensuring reliable pumps operate effectively. Regular maintenance not only enhances pump operation but also identifies the new pump status, which helps in preempting imminent pump failure. Following established maintenance guidelines allows for a smoother maintenance program, incorporating both essential monthly tasks and proper maintenance practices. Utilizing appropriate facility maintenance tools during these checks ensures that any potential issues are addressed promptly, thus extending the lifespan of the equipment. Adhering to this routine ultimately supports the overall efficiency and reliability of your pumping systems.

Essential Monthly Tasks

Monthly maintenance is crucial for ensuring the longevity and efficiency of your quality pump. A thorough pump maintenance checklist should include tasks such as inspecting the system for leaks, checking the functionality of the check valves, and assessing the seals and gaskets for wear. Regularly scheduled monthly maintenance can help identify issues, such as a faulty check valve, before they escalate into more significant problems. Following a structured maintenance plan can significantly reduce the risk of costly repairs and enhance the overall performance of the pump.

Implementing a comprehensive monthly maintenance checklist allows operators to stay proactive in their pump care. This includes cleaning components, checking fluid levels, and ensuring that all electrical connections are secure. By adhering to maintenance schedules that encompass both monthly and annual maintenance, facilities can benefit from streamlined pump solutions and enhance operational reliability. Incorporating these tasks into a pump remanufacture program can also optimize efficiency and extend the life of the pump.

- Regularly clean the pump and its components to prevent buildup and damage.

- Monitor operating temperatures to ensure they remain within optimal ranges.

- Test and calibrate pressure gauges for accuracy.

- Replace any worn or damaged parts immediately to maintain performance.

- Document all maintenance activities to track history and compliance.

- Review and update the maintenance checklist as needed to reflect any changes in operation.

- Train staff on proper pump maintenance techniques and the importance of adherence to the checklist.

Tools Needed for Monthly Maintenance

A well-rounded pump maintenance checklist is essential to ensuring that all necessary tools are readily available for monthly inspections. Basic maintenance activities require the right equipment, including wrenches, screwdrivers, and a multimeter for electrical checks. A maintenance schedule should clearly outline which tools are needed for each task to streamline the process. General maintenance personnel should familiarize themselves with these tools, as this knowledge is crucial for executing proactive maintenance effectively.

Routine maintenance schedules also benefit from having a dedicated toolbox for monthly tasks. Tools like pressure gauges and flow meters are vital for evaluating pump performance, while specialized equipment may be necessary for flushing pumps. The comprehensive maintenance plan should detail the specific tools required, facilitating efficient completion of the following maintenance points. By being properly equipped, maintenance teams can ensure that every aspect of pump care is addressed thoroughly in line with the pump maintenance checklist.

Quarterly Pump Maintenance Steps

A thorough understanding of systematic maintenance is essential for effective pump maintenance. The pump maintenance checklist for quarterly intervals includes maintenance tasks tailored to specific pump types and their operating environments. Regular maintenance safeguards against unexpected failures and prolongs the life of the equipment. Key actions include checking pump alignment, assessing fluid levels, and ensuring proper lubrication. Evaluating the pump’s performance during these checks helps identify future maintenance needs and facilitates adjustments based on typical pump placement. Following a structured checklist not only ensures efficiency but also supports long-term operational reliability.

Recommended Actions for Quarterly Checks

Quarterly checks should focus on thorough evaluations to ensure optimal pump performance. Utilize a pump maintenance checklist to guide the review of critical components like seals, bearings, and connections. For facilities using external flush pumps, verify the condition of the flushing system as part of the maintenance activities. Employ facility maintenance software to track these checks and keep accurate maintenance records. It’s important to adhere to a regular maintenance schedule, which can prevent larger issues from arising.

Reviewing the manufacturer’s guidelines is essential in customizing your quarterly maintenance activities. This helps to accommodate any specific requirements for the pump type in use, maintaining consistency in upkeep. Depending on the size of your operation, consider expanding your maintenance checklist for larger systems. Establishing a large maintenance schedule may involve more detailed inspections, ensuring that every aspect of your pump works efficiently.

Evaluating Pump Performance

Monitoring pump performance is crucial for understanding the effectiveness of your preventive maintenance policy. A detailed pump maintenance checklist can help identify key performance indicators such as flow rate and energy consumption. Insights gained from these evaluations can be beneficial when working with pump manufacturers for sourcing new pump components. Regularly reviewing this information enables operators to catch potential issues early and perform important maintenance tasks efficiently.

Quarterly maintenance checks serve as an optimal opportunity to utilize maintenance software for tracking pump performance over time. With the integration of pump switches and other monitoring devices, operators can easily document data on wear and tear. This proactive approach can highlight the need to repair components before they lead to significant downtime. Adhering to a comprehensive pump maintenance checklist will ensure that all critical areas are assessed, ultimately enhancing the longevity and efficiency of the equipment.

| Performance Indicator | Description | Ideal Value | Measurement Frequency |

|---|---|---|---|

| Flow Rate | Volume of fluid that the pump moves over a specified period | Depends on system requirements | Quarterly |

| Energy Consumption | Amount of energy used by the pump during operation | Minimized for efficiency | Monthly |

| Vibration Levels | Measure of vibrations from the pump components indicating wear | Low levels (varies by pump type) | Monthly |

| Temperature | Operating temperature of the pump components | Within manufacturer’s specifications | Quarterly |

| Fluid Leakage | Presence of any fluid escaping from pump seals | No leaks | During inspections |

Annual Pump Maintenance Guidelines

Regular adherence to a comprehensive pump maintenance checklist is essential, especially during annual inspections. This involves evaluating the preventive maintenance schedule and ensuring that all components, including the secondary pump and backup sump pump, receive proper attention. Checking for oil leaks is crucial, alongside performing bearing maintenance to sustain optimal pump efficiency. Utilizing pump selection guides can also aid in identifying the best practices tailored to each pump’s specific needs. Conducting a maintenance audit can highlight areas for improvement and lead to better long-term performance. Prioritizing these annual tasks ensures the reliability and effectiveness of your pumping systems.

Comprehensive Annual Maintenance Checklist

A thorough pump maintenance checklist is vital for ensuring the efficient operation of industrial pumps throughout the year. Annual inspections should include reviewing external pump directs and assessing the overall pump vibration of the unit. Each maintenance task should align with the specifications outlined for standard pump models and specific sump pump system requirements. Utilizing preventive maintenance software can help track maintenance frequency and ensure that no critical tasks are overlooked during these comprehensive evaluations.

The annual maintenance checklist should encompass both mechanical and electrical components of the pump unit. Inspect seals, bearings, and connections to identify any signs of wear or potential failures. Calibration and testing of safety features must also be part of this checklist. Following these steps not only enhances the lifespan of the pump but also contributes to operational efficiency and reliability in various applications.

Importance of Annual Inspections

Annual inspections play a crucial role in ensuring the longevity and efficiency of various pumps, including pedestal pumps and sump pump components. A comprehensive pump maintenance checklist during these inspections typically includes critical tasks such as checking bearing oil, examining the shaft, and assessing motor insulation. Implementing a thorough annual checklist maximizes the performance of pumps and minimizes unexpected breakdowns, which can significantly disrupt operations.

Incorporating annual inspections into a preventative maintenance plan helps identify potential issues before they escalate. Regular system inspections not only maintain the reliability of pumps but also enhance overall operational efficiency. Each inspection should systematically verify all essential components, ensuring that every part functions as intended and meets safety standards. This meticulous approach fosters a well-maintained pumping system, ultimately leading to reduced repair costs and extended equipment lifespan.

Customizing Your Maintenance Checklist

Creating an effective pump maintenance checklist requires careful consideration of several factors unique to each system. For instance, a professional sump pump might necessitate more frequent checks compared to other pump stations due to its critical role in preventing flooding. An old pump may exhibit issues that are not present in newer models, emphasizing the need for tailored mechanical inspection procedures. Implementing daily checklists can help identify potential problems early, while monthly maintenance appointments ensure that all pumps—especially those experiencing infrequent maintenance—are performing optimally. Pay attention to components like the sump pump breaker to avoid costly failures. Customization helps enhance system reliability and prolongs the lifespan of your pumps.

Factors to Consider for Specific Pumps

Specific pumps require tailored approaches in their maintenance checklist to ensure optimal performance. This includes frequent pressure checks, which help identify decreased pump performance early on. It’s vital to inspect starter/contractor functionality regularly to minimize the risk of unexpected breakdowns. Keeping a detailed maintenance history allows for identifying patterns in repairs and can guide future operational strategies.

Pumps can exhibit unique issues that necessitate careful monitoring. Excessive pump vibration may indicate problems with alignment or imbalance, requiring checks on shaft runout. For a proper sump pump function, understanding its specific requirements is essential. Each pump type may have different needs, and customizing the pump maintenance checklist ensures that all critical aspects are covered effectively.

Tailoring the Checklist to Operational Needs

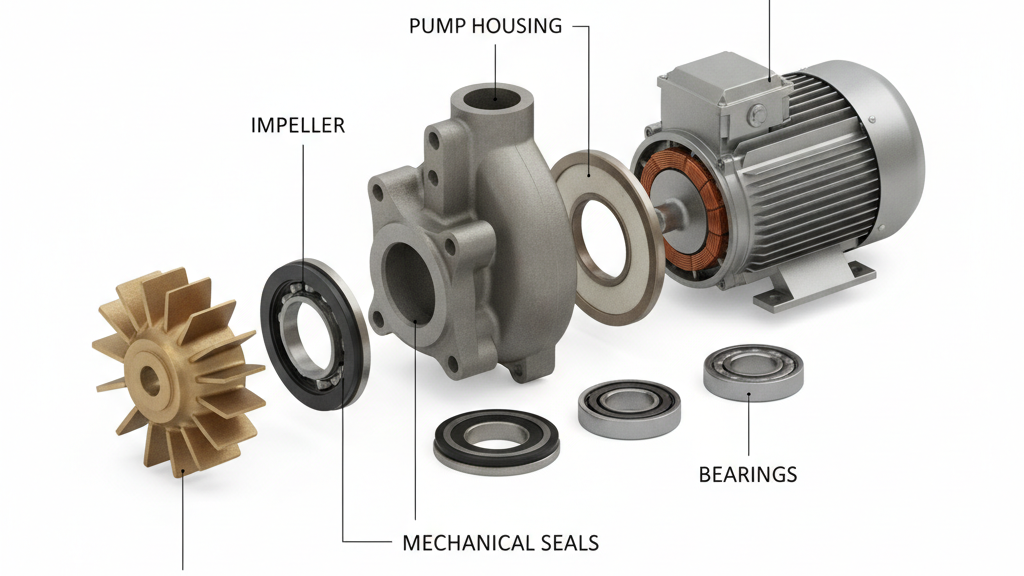

Creating a customized pump maintenance checklist is essential to match specific operational needs. Factors such as the type of pump—whether it’s a primary pump or a sump pump—can significantly influence the tasks included. For instance, focusing on checks related to pump seals and pump impellers is vital to prevent leaks and maintain optimal performance. The maintenance team should pay close attention to pump vibration and pump bearing conditions as these indicators can signal potential issues that may affect overall system reliability.

Operational conditions also dictate how often certain tasks should be performed. High-demand environments may require stricter schedules, while less intensive applications may allow for more flexibility. Increasing pump efficiency hinges on proper maintenance routines, including regular inspections of the sump pump area and proactive checks on critical components. By tailoring the pump maintenance checklist to specific operational needs, facilities can enhance reliability and prolong the lifespan of their pumps.

Troubleshooting Common Pump Issues

Identifying signs of pump failure is crucial for maintaining the efficiency of your pump systems. A thorough pump maintenance checklist helps in spot-checking various components, especially under different hydraulic loads. Issues in a pedestal sump pump or a centrifugal pump system often surface through unusual noises, vibrations, or leaks. Regular product inspections utilizing the right inspection tools can reveal early signs of wear. Timely repair actions, including potential pump exchange for self-flush pumps, can significantly extend the lifespan of your pumps asset. Incorporating these practices into your maintenance routine ensures that you address problems proactively and sustain optimal performance.

| Issue | Symptoms | Possible Causes | Recommended Actions |

|---|---|---|---|

| Unusual Noise | Clicking, whining, or grinding sounds | Worn bearings, misalignment, or cavitation | Inspect for alignment issues; replace bearings |

| Vibrations | Excessive shaking; instability during operation | Imbalance, misalignment, or foundation issues | Check and correct alignment; secure foundation |

| Leaks | Water pooling around the pump; visible fluid loss | Damaged seals, loose fittings, or cracks | Replace seals; tighten fittings and inspect body |

| Pump Not Starting | No sound or movement when activated | Electrical issues, blown fuses, or control failure | Check power supply; test controls and fuses |

Identifying Signs of Pump Failure

Signs of pump failure can often be detected through vigilant monitoring and regular adherence to a pump maintenance checklist. A critical first step is to check oil level regularly, as both low oil and contamination can lead to operational issues. Any fluctuations in pressure readings should also be recorded, as they could indicate underlying problems. Routine inspections of components, including the gasket, are vital to identifying leaks or wear that may jeopardize pump functionality.

Unusual noises or vibrations during operation can signal imminent pump failure. A thorough examination of the system using the pump maintenance checklist can help pinpoint these disturbances. Observing the housing for signs of excessive heat is essential, as overheating may indicate a malfunction. By staying attentive to these warning signs, operators can prevent costly damage and ensure the longevity of their pumping systems.

Conclusion

Implementing a thorough pump maintenance checklist is essential for the longevity and efficiency of any pumping system. Establishing a routine maintenance schedule helps in identifying issues before they escalate into major problems. Basic maintenance activities, such as daily maintenance tasks and flushing pumps, should be integrated into a comprehensive maintenance plan tailored to specific operational needs. Following maintenance points diligently ensures that general maintenance personnel can effectively manage pump performance. Regular assessments and adjustments to the maintenance schedule are vital for proactive maintenance, ensuring pumps operate efficiently and reducing downtime.

FAQS

What should I include in my monthly pump maintenance routine to ensure the longevity and efficiency of my pumps?

For effective monthly pump maintenance, it’s crucial to follow a preventive pump maintenance approach. Start by using a regular maintenance checklist to inspect pumps thoroughly. Make sure to check the oil leaks, inspect the shaft pump, and test pumps to ensure they operate efficiently. In particular, focus on centrifugal pump maintenance by checking the bearing oil and shaft runout, and verifying motor insulation. Additionally, ensure the pump environment is optimal. By choosing a well-structured maintenance programs like Pumpworks, you can help achieve consistent maintenance, which ultimately contributes to increased pump efficiency. Be sure to inspect gaskets regularly as part of a comprehensive maintenance checklist, especially when dealing with several pumps.

How can I create an effective pump maintenance checklist to ensure I properly check the pump and inspect the shaft pump?

An effective pump maintenance checklist should include steps to check pump performance, inspect shaft pump alignment, check for oil leaks, and choose pumpworks that fit your operational needs. Additionally, you should check bearing oil levels, check the shaft for wear, and check motor insulation for any signs of degradation. Regular checks of shaft runout are also essential since proper maintenance of your primary pump isn’t just about fixing issues but preventing them.

What specific tasks should I prioritize in my pump maintenance checklist to effectively check oil leaks and shaft runout?

A comprehensive pump maintenance checklist should include tasks such as checking oil leaks, inspecting the shaft for wear or damage, and measuring the shaft runout. Regularly checking these aspects during your maintenance routine is crucial, as proper pump maintenance involves ensuring these components are in working order to extend the life of your pumps.

How should I structure my pump maintenance checklist to effectively check oil leaks and check shaft conditions?

To structure your pump maintenance checklist effectively, make sure to include specific sections that focus on tasks such as checking oil leaks, inspecting the shaft for any wear or damage, and assessing pump performance. Regularly checking shaft runout is also critical as it helps in identifying misalignment issues. Comprehensive pump maintenance involves not only these tasks but also ensuring that all components are operating within their specified parameters to prevent future problems.

What actions should I take in my pump maintenance checklist to ensure I can effectively check oil leaks and monitor shaft performance?

An effective pump maintenance checklist should include steps to check oil leaks, examine the shaft, and evaluate the overall condition of the pumps. Regular inspections of components are crucial, and focusing on tasks that help check shaft runout is essential for optimal pump performance. Proper maintenance involves routine checks that contribute to the longevity and efficiency of your pumps.

How can I ensure that my pump maintenance procedures are comprehensive and cover all necessary aspects of pump upkeep?

Proper maintenance of pumps involves regular inspections, lubrication, checking for oil leaks, and monitoring performance metrics to enhance efficiency and lifespan.

Comments are closed.